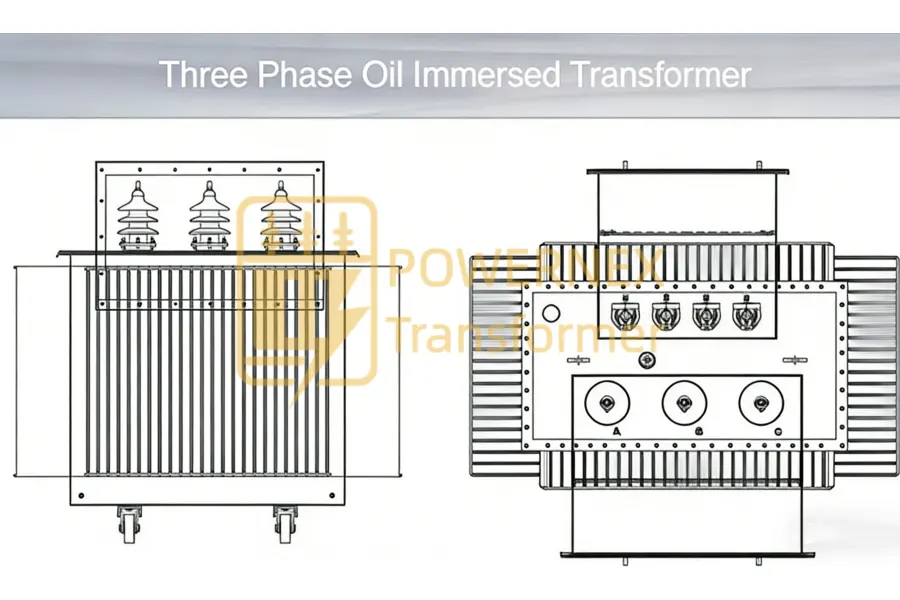

The 500 kVA (11–35 kV) three phase oil immersed distribution transformer is a medium-voltage electrical distribution solution designed for utility substations, regional power networks, and industrial distribution systems requiring stable voltage transformation, high efficiency, and long-term operational reliability.

This transformer is engineered to support modern electrical grids operating under diverse environmental conditions and regulatory standards. With flexible voltage configurations, robust oil-immersed insulation, and compatibility with both 50 Hz and 60 Hz systems, it is widely deployed in utility distribution projects across North America, South America, Europe, the Middle East, Africa, and the Asia-Pacific region.

The 500 kVA rating makes it an optimal capacity for urban and semi-urban substations, feeder reinforcement, industrial power supply points, and infrastructure distribution networks where balanced performance, cost efficiency, and scalability are essential.

Technical Specifications

| Item | Specification |

|---|---|

| Rated Capacity | 500 kVA |

| Capacity Range Available | 100 kVA – 5000 kVA |

| Transformer Type | Three Phase Oil Immersed Medium Voltage Transformer |

| Primary Voltage Range | 11 kV / 12.47 kV / 13.8 kV / 22 kV / 24.9 kV / 33 kV / up to 35 kV |

| Secondary Voltage Options | 208Y/120 V, 380 V, 400 V, 415 V, 480 V, 600 V, 690 V or customized |

| Frequency | 50 Hz / 60 Hz |

| Vector Group | Dyn11, Yyn0, Yd11, Dd0 or customized |

| Cooling Method | ONAN standard (ONAF optional) |

| Insulating Fluid | Mineral oil or environmentally friendly ester oil |

| Tap Changer | Off-circuit tap changer ±2×2.5% or ±5% (OLTC optional) |

| Impedance | Customized according to system requirements |

| Applicable Standards | IEC, ANSI, IEEE |

| Optional Certifications | UL, cUL, CSA, CE |

| Installation Type | Outdoor substation / pad-mounted / utility distribution |

Oil Immersed Design & Thermal Performance

Oil immersed transformer technology remains the preferred solution for utility and substation applications due to its superior thermal management and dielectric strength.

The transformer core and windings are fully submerged in insulating oil, which serves dual functions:

-

Electrical insulation, preventing partial discharge and breakdown

-

Heat dissipation, transferring thermal energy from windings to tank surfaces

This design allows the 500 kVA transformer to operate continuously under rated load while maintaining stable temperature rise, even in high-ambient or heavy-load conditions.

Optional ONAF cooling enhances thermal performance during peak demand, ensuring operational stability for utility grids experiencing seasonal or load-driven fluctuations.

Core & Winding Engineering

High-Efficiency Core Design

The transformer core is manufactured using cold-rolled grain-oriented silicon steel, precisely laminated to reduce hysteresis and eddy current losses. This results in:

-

Lower no-load losses

-

Improved voltage regulation

-

Higher overall system efficiency

Precision Winding Construction

Copper or aluminum conductors are available based on customer preference and regional standards. Windings are engineered with:

-

Uniform current distribution

-

High short-circuit withstand strength

-

Enhanced mechanical rigidity

This ensures stable operation during transient conditions such as inrush currents, load switching, or system faults.

Voltage Flexibility & Customization Capability

The 500 kVA oil immersed transformer supports a wide range of medium-voltage primary inputs and low-voltage secondary outputs, making it adaptable to local grid standards and project-specific requirements.

Custom options include:

-

Special voltage ratios

-

Multi-tap configurations

-

Customized impedance values

-

Non-standard vector groups

-

Special insulation classes

This flexibility allows seamless integration into utility networks across the US, Canada, Australia, Brazil, Argentina, Mexico, Malaysia, Indonesia, Saudi Arabia, UAE, Europe, and Africa.

Applications in Utility & Distribution Systems

This transformer is widely applied in:

Electrical Substations

Used for step-down voltage transformation from medium-voltage feeders to low-voltage distribution systems, ensuring stable and reliable power delivery.

Utility Distribution Networks

Installed at feeder points to balance load, reduce voltage drops, and improve overall grid stability.

Industrial Power Distribution

Supports manufacturing plants, processing facilities, and industrial parks requiring consistent voltage and high operational reliability.

Infrastructure & Commercial Projects

Ideal for transportation hubs, hospitals, data centers, municipal facilities, and commercial complexes.

Renewable Energy Integration

Acts as a distribution interface for solar farms, wind power systems, and hybrid energy projects.

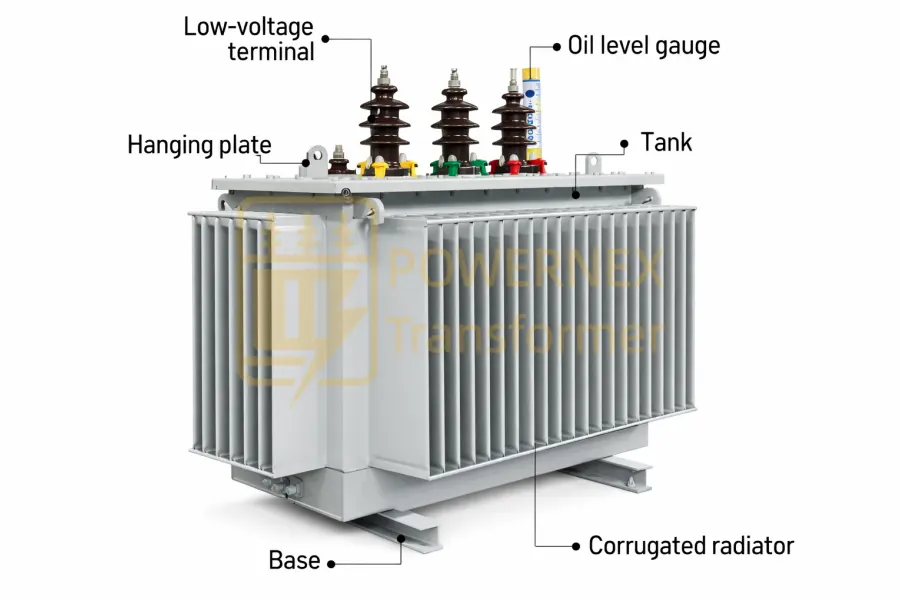

Mechanical Structure & Outdoor Protection

The transformer tank is constructed from high-strength steel plates, fully welded and sealed to prevent moisture ingress and oil leakage.

Protective features include:

-

Corrosion-resistant surface coating

-

Weatherproof bushings

-

Pressure relief devices

-

Oil level indicators and temperature gauges

This makes the transformer suitable for outdoor installation in coastal, desert, tropical, or industrial environments.

Safety, Reliability & Service Life

The transformer is designed with multiple safety mechanisms:

-

Over-pressure protection

-

Thermal monitoring options

-

Short-circuit withstand design

-

High dielectric margin

These features significantly extend service life and reduce maintenance requirements, making it a cost-effective solution for long-term utility operation.

Testing & Quality Assurance

Each transformer undergoes comprehensive factory testing, including:

-

Winding resistance measurement

-

Voltage ratio and vector group verification

-

No-load and load loss testing

-

Insulation resistance and dielectric tests

Optional type and special tests can be performed based on project requirements.

Compliance with International Standards

Manufactured in accordance with:

-

IEC standards for global compatibility

-

ANSI / IEEE standards for North American markets

Optional certifications such as UL, cUL, CSA, and CE support regulatory approval across different regions, simplifying procurement and project execution.

Logistics, Packaging & Global Delivery

The transformer is securely packed for international transport, with options for:

-

Fully oil-filled delivery

-

Nitrogen-filled shipment

-

Sea-worthy wooden or steel packaging

Global logistics support ensures timely delivery to project sites worldwide.

Why This 500 kVA Transformer Is a Smart Choice

-

Optimized capacity for utility distribution

-

Wide voltage adaptability (11–35 kV)

-

Proven oil-immersed reliability

-

Global standards compliance

-

OEM customization and factory-direct supply

-

Long service life with low operating cost

Conclusion

The 500 kVA (11–35 kV) three phase oil immersed transformer is a dependable and versatile solution for electrical substations and utility distribution systems worldwide. Its advanced engineering, flexible configuration options, and robust construction make it suitable for a wide range of power distribution applications across diverse markets.

Designed to meet international standards and demanding operating conditions, this transformer delivers stable performance, high efficiency, and long-term reliability for modern power networks.

FAQ – 500 kVA Three Phase Oil Immersed Transformer

What is a 500 kVA three phase oil immersed transformer used for?

It is widely used in electrical substations, utility distribution networks, and industrial power systems to step down medium voltage (11–35 kV) to low-voltage levels for reliable power supply.

What voltage options are available?

Primary voltage ranges from 11 kV to 35 kV, including 11 kV, 13.8 kV, 22 kV, 24.9 kV, and 33 kV. Secondary voltages typically include 400 V, 415 V, 480 V, 600 V, and 690 V. Custom voltage ratios are supported.

Is it suitable for global power systems?

Yes. The transformer supports both 50 Hz and 60 Hz operation and complies with IEC, ANSI, and IEEE standards for global utility and industrial applications.

What capacity options are available?

We support a wide range of transformer capacities including 200 kVA, 225 kVA, 300 kVA, 500 kVA, 750 kVA, 1000 kVA, as well as other customized ratings for different electrical substation and utility distribution applications.

What cooling methods are used?

Standard ONAN oil-immersed cooling is provided, with optional ONAF for higher load or temperature conditions.

Can the transformer be customized?

Yes. Vector group, impedance, insulation level, enclosure type, and certifications (UL, cUL, CSA, CE) can be customized based on project requirements.

Is it designed for outdoor installation?

Yes. It features a sealed steel tank with corrosion-resistant coating, suitable for outdoor substations and harsh environments.

Why Buy From Us – Factory Direct Supply

Factory Price, No Middlemen

Direct manufacturing ensures competitive pricing for wholesale and project orders.

Proven Utility & Substation Experience

Designed for long-term operation in utility grids, substations, and industrial distribution systems.

Flexible Custom Design

Full customization for voltage, vector group, cooling, and standards (IEC / ANSI / IEEE).

Certified for Global Markets

Optional UL, CSA, CE certifications available for international projects.

Strict Quality Control

Each transformer is factory-tested to ensure performance, safety, and reliability.

Worldwide Delivery & Support

Export packaging, global shipping, and responsive technical support from inquiry to operation.

Reviews

There are no reviews yet.