Power Transformers, Automatic Voltage Regulators (AVR), Variable Voltage Regulators & VFD Systems for Industrial, Utility, and Infrastructure Projects Worldwide

PowerNex provides system-level industrial power solutions, combining power transformers, voltage regulation systems, and motor control technologies into fully coordinated electrical systems. Our solutions are engineered to deliver stable voltage, high load capacity, and long-term operational reliability for industrial plants, utilities, EPC contractors, and infrastructure developers worldwide.

✔ Capacity Range: 1 kVA – 40,000 kVA

✔ Voltage Range: 110V – 35kV (Low & Medium Voltage)

✔ Single-Phase & Three-Phase

✔ 50Hz / 60Hz Power Systems

✔ Factory-Direct Manufacturing, OEM & Wholesale Supply

Why System-Level Power Solutions Are Critical in Modern Projects

In today’s industrial and utility environments, electrical systems face increasing complexity due to:

-

Fluctuating utility grid voltage

-

High motor starting currents

-

VFD-induced harmonics and heat stress

-

Continuous and variable production loads

-

Different voltage standards across global regions

Selecting individual components without system coordination often leads to:

-

Voltage drops and instability

-

Transformer overheating

-

Motor failures and nuisance trips

-

Reduced equipment lifespan

PowerNex focuses on complete power system engineering, ensuring transformers, voltage regulators, and motor control equipment operate as a unified, optimized solution—not isolated products.

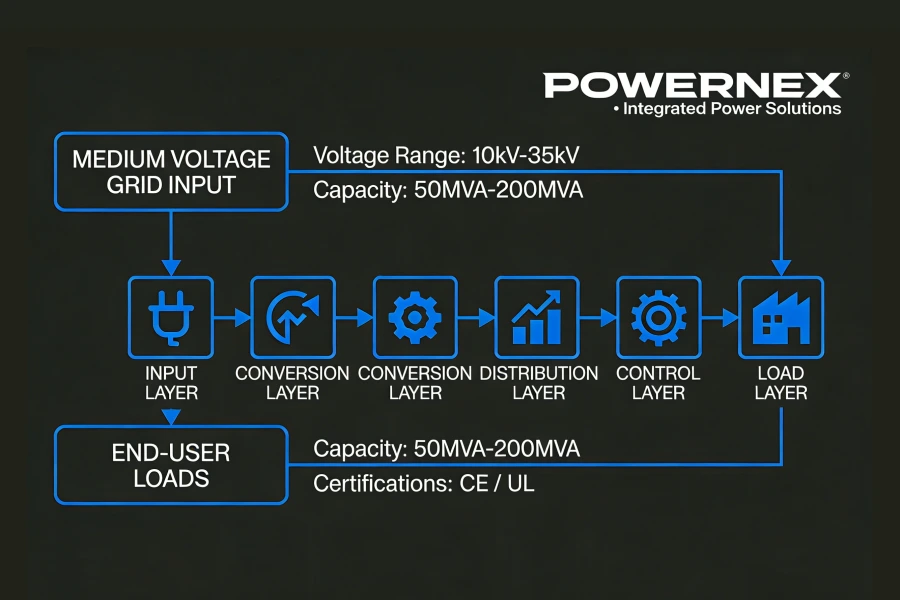

Typical Industrial Power System Architecture

Medium Voltage Grid (10kV / 11kV / 20kV / 33kV)

→ Medium Voltage Power Transformer

→ Low Voltage Distribution (400V / 415V / 480V / 600V)

→ Automatic Voltage Regulator (AVR) or Variable Voltage Regulator

→ Variable Frequency Drives (VFDs)

→ Motors, Production Lines, and Process Equipment

Each layer is designed to handle load characteristics, voltage fluctuations, and long-term operating conditions.

Core Power System Components & Technical Specifications

1. Power Transformers – Voltage Conversion & Load Management

PowerNex manufactures a full range of industrial and utility-grade transformers:

Transformer Types

-

Dry-Type Transformers

-

Oil-Immersed Power Transformers

-

Isolation Transformers

-

Distribution Transformers

-

Pad-Mounted Transformers

-

Pole-Mounted Transformers

Technical Range

-

Capacity: 1 kVA – 40,000 kVA

-

Primary Voltage: 110V – 35kV

-

Secondary Voltage: 110V / 208V / 220V / 380V / 400V / 415V / 480V / 600V

-

Phase: Single-Phase / Three-Phase

-

Cooling: AN / AF / ONAN / ONAF

-

Standards: IEC, ANSI, IEEE, UL, CE

Designed for continuous duty in industrial plants, substations, renewable energy systems, and infrastructure projects.

2. Voltage Regulation Systems – Power Quality & Stability

Stable voltage is essential for protecting electrical equipment and maintaining production efficiency.

Available Solutions

-

Automatic Voltage Regulators (AVR)

-

Low Voltage & Medium Voltage Regulation Systems

Key Functions

-

Correct over-voltage and under-voltage conditions

-

Stabilize fluctuating utility supply

-

Protect sensitive automation and control systems

-

Reduce downtime and maintenance costs

Voltage regulators are engineered to match transformer capacity and downstream load requirements.

3. Variable Frequency Drives (VFDs) – Motor Control & Energy Efficiency

VFD systems are widely used to control motor speed, torque, and energy consumption.

Typical Specifications

-

Voltage: 380V / 400V / 415V / 480V / 600V

-

Applications: Pumps, fans, compressors, conveyors, mixers

PowerNex provides VFD-compatible transformer solutions, including isolation and harmonic-mitigating designs, to reduce heat, noise, and electrical stress.

Engineering Focus: Capacity & Voltage Coordination

Transformer Capacity Selection

-

Based on total connected load

-

Motor starting current considerations

-

Harmonic derating for VFD applications

-

20–30% capacity margin for future expansion

Voltage Regulation Matching

-

Regulator capacity equal to or greater than transformer output

-

Designed for continuous and dynamic load variations

Global Voltage Compatibility

-

North America: 480V / 600V / 60Hz

-

Europe: 400V / 50Hz

-

Southeast Asia: 380V–415V / 50Hz

-

Africa & South America: Custom LV/MV configurations

Real Engineering Application Example

Project Type: Industrial Manufacturing Facility

Location: International Project

System Configuration

-

2500 kVA Oil-Immersed Transformer (10kV / 400V)

-

2000 kVA Automatic Voltage Regulator

-

Multiple VFD-Controlled Motor Loads

Results

-

Stable voltage under heavy load fluctuations

-

Reduced motor overheating and failures

-

Improved production continuity

-

Scalable design for future capacity growth

Custom Engineering & Factory Manufacturing

As a China-based power equipment manufacturer with in-house engineering and factory-controlled production, PowerNex supports:

-

Custom voltage and capacity configurations

-

Integrated transformer + AVR + VFD system design

-

Indoor & outdoor installations

-

OEM manufacturing and wholesale supply

-

Project-based and EPC support

Global Markets Served

United States, Canada, Brazil, Argentina, Mexico, South Africa, Indonesia, Malaysia, and worldwide.

Industries & Applications

-

Industrial Manufacturing & Processing Plants

-

Utilities & Power Grid Projects

-

Infrastructure & Transportation Systems

-

Renewable Energy (Solar & Wind)

-

Commercial Buildings & Large Facilities

-

Water Treatment, Oil & Gas, Mining

Why Choose a System Solution Instead of Individual Equipment?

✔ Reduced engineering risk

✔ Optimized electrical performance

✔ Faster installation & commissioning

✔ Single-source responsibility

✔ Long-term system reliability

A coordinated power system delivers better performance than disconnected components.

Talk to Our Engineering Team

Whether you are planning a new installation, upgrading an existing system, or developing a project-based solution, PowerNex provides professional technical support from concept to production.

👉 Request a Technical Consultation

👉 Get a Custom Power System Proposal

👉 Factory-Direct OEM & Wholesale Supply