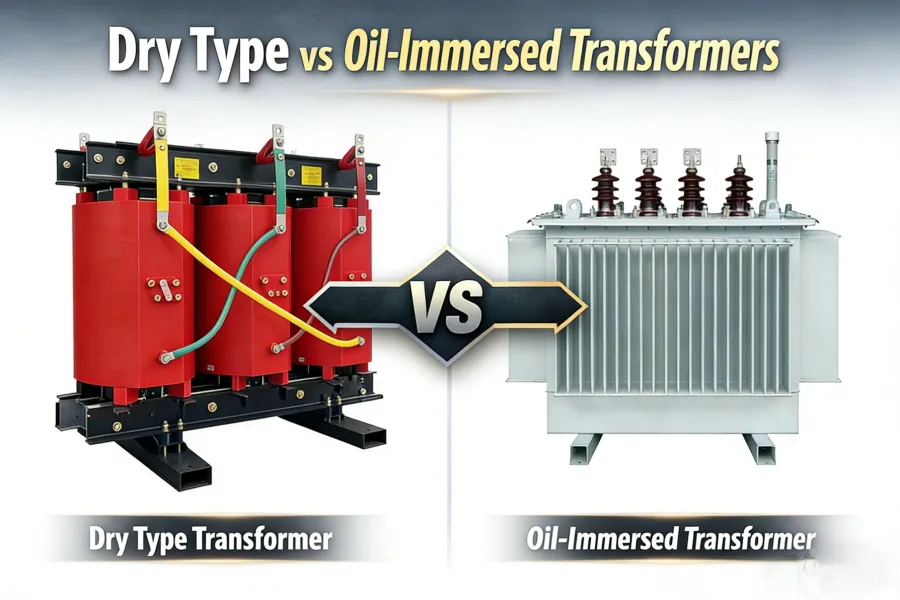

Selecting the right transformer is a critical decision in industrial, commercial, and utility power system design. Dry type transformers and oil-immersed transformers are the two most widely used transformer technologies, each offering distinct advantages depending on capacity range, voltage level, installation environment, and application requirements.

This comprehensive guide compares dry type and oil-filled transformers in terms of kVA capacity, voltage ratings, cooling methods, safety considerations, and typical applications, helping engineers, EPC contractors, and project owners make informed decisions.

Dry Type Transformers: Capacity Range, Voltage Levels & Applications

A dry type transformer uses air as the cooling medium and solid insulation systems instead of insulating oil. These transformers are commonly selected for indoor installations, fire-sensitive environments, and locations requiring low maintenance and clean operation.

Typical Electrical Parameters of Dry Type Transformers

Dry type transformers are generally designed for low-voltage and medium-voltage power distribution, with the following typical specifications:

-

Rated capacity: 1 kVA – 3000 kVA

-

Primary voltage: 208 V / 380 V / 400 V / 480 V / 600 V / up to 35 kV

-

Secondary voltage: 120 V / 208 V / 220 V / 380 V / 400 V / 480 V

-

Phase: Single-phase or three-phase

-

Frequency: 50 Hz / 60 Hz

-

Insulation class: Class F or Class H

-

Cooling method: AN (Air Natural) / AF (Air Forced)

These ratings make dry type transformers ideal for installations where equipment is located close to personnel and sensitive loads.

Common Applications of Dry Type Transformers

Dry type transformers are widely used in:

-

Industrial manufacturing plants and production lines

-

Commercial buildings and office complexes

-

Data centers and IT infrastructure

-

Hospitals and healthcare facilities

-

Airports, metro systems, and public infrastructure

They are often combined with isolation transformers, automatic voltage regulators (AVR), and variable frequency drives (VFDs) to protect sensitive equipment and ensure stable voltage under fluctuating load conditions.

Oil-Immersed Transformers: Capacity Up to 40,000 kVA

Oil-immersed transformers, also known as oil-filled transformers, use insulating oil for both cooling and dielectric strength. This design allows for significantly higher power density, superior thermal performance, and long-term continuous operation.

Typical Electrical Parameters of Oil-Immersed Transformers

PowerNex oil-immersed transformers are engineered to cover a wide capacity range from 10 kVA up to 40,000 kVA (40 MVA), making them suitable for both distribution and utility-scale power systems.

-

Rated capacity: 10 kVA – 40,000 kVA

-

Primary voltage:

-

Secondary voltage: 400 V / 415 V / 480 V / 690 V / customized LV outputs

-

Phase: Three-phase (single-phase available upon request)

-

Frequency: 50 Hz / 60 Hz

-

Cooling methods: ONAN / ONAF / OFAF

-

Installation: Outdoor, substation-mounted, pad-mounted, or pole-mounted

This extended capacity range enables oil-immersed transformers to support heavy industrial loads, utility substations, renewable energy interconnections, and infrastructure-scale power projects.

Applications of Large-Capacity Oil-Immersed Transformers (Up to 40 MVA)

Oil-immersed transformers rated from several MVA up to 40 MVA are widely deployed in:

-

Utility transmission and distribution substations

-

Industrial power plants and captive power generation systems

-

Solar and wind farm step-up substations

-

Mining, oil & gas, and petrochemical facilities

-

Water treatment plants and pumping stations

-

Large EPC and infrastructure projects

The oil insulation system provides excellent heat dissipation, high overload capability, and long service life, making these transformers suitable for continuous-duty operation under demanding conditions.

Key Differences Between Dry Type and Oil-Immersed Transformers

Capacity & Power Density

Dry type transformers typically serve low to medium capacities, while oil-immersed transformers support much higher kVA ratings, including utility-class transformers up to 40,000 kVA.

Voltage Level

Dry type designs are commonly used below 35 kV, whereas oil-filled transformers dominate medium- and high-voltage power distribution and sub-transmission systems.

Installation & Safety

Dry type transformers are preferred for indoor applications due to their fire safety and clean operation. Oil-immersed transformers require proper oil containment, fire protection, and outdoor installation planning.

Efficiency & Thermal Performance

Oil cooling allows for superior heat transfer, making oil-immersed transformers more efficient and suitable for long-term high-load operation.

Maintenance Requirements

Dry type transformers require minimal routine maintenance, while oil-filled transformers require periodic oil testing and monitoring to maintain insulation performance.

How to Choose the Right Transformer for Your Project

When selecting a transformer, engineers should consider:

-

Required capacity (kVA / MVA) and voltage class

-

Installation environment (indoor or outdoor)

-

Load characteristics and duty cycle

-

Applicable standards (IEC, ANSI, IEEE, UL, CE, CSA)

-

Power quality and protection requirements

Projects involving sensitive equipment may require integrated solutions including AVR systems, variable voltage regulators, VFDs, and motor control centers (MCC).

Integrated Transformer & Voltage Regulation Solutions

Modern electrical systems often combine transformers with advanced voltage regulation and power quality equipment, such as:

-

Automatic Voltage Regulators (AVR)

-

Variable Voltage Regulators

-

Variable Frequency Drives (VFDs)

-

Motor Control Centers (MCC)

Manufacturers with in-house engineering and factory-controlled production can provide customized solutions based on voltage levels, capacity ranges, environmental conditions, and local grid requirements.

Work with a Professional Transformer Manufacturer

An experienced transformer manufacturer can support projects ranging from 1 kVA control transformers to 40 MVA oil-immersed power transformers, offering:

-

Customized design and engineering

-

Compliance with IEC, ANSI, and IEEE standards

-

Comprehensive factory testing

-

Long-term technical and after-sales support

Choosing the right manufacturing partner ensures reliable power distribution, operational safety, and long-term system stability.

Discuss Your Transformer Requirements

Whether you are planning a new installation, upgrading existing power systems, or developing a large-scale industrial or utility project, professional technical support is essential.

Contact PowerNex to discuss your transformer capacity, voltage ratings, and application requirements and receive a customized power solution engineered for reliable performance.