Installation Requirements, Safety Considerations, and Environmental Selection Guide

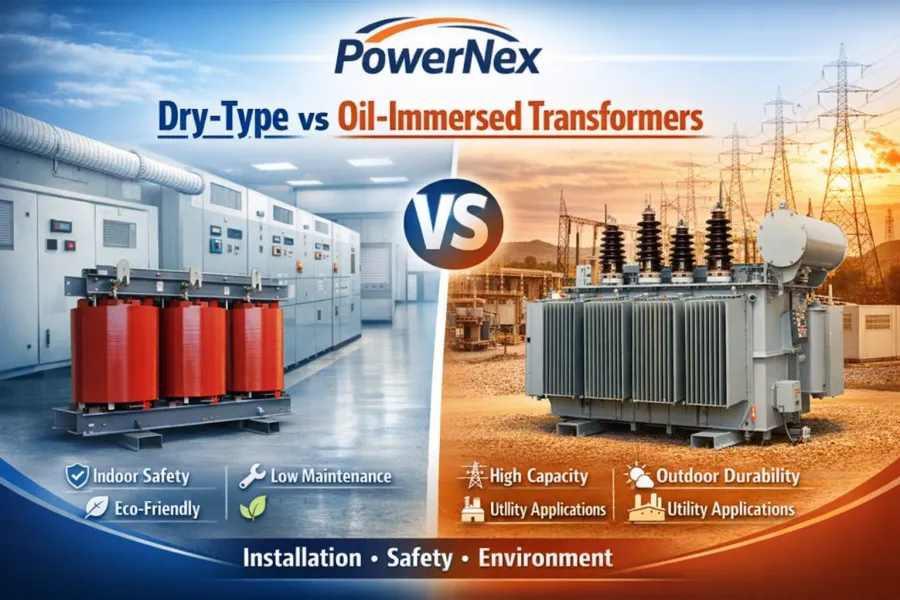

As industrial power systems and utility networks continue to expand, selecting the right transformer type is not only about capacity and voltage ratings, but also about installation environment, safety requirements, maintenance conditions, and long-term operational risk.

This article provides a practical comparison between dry-type transformers and oil-immersed transformers, focusing on installation conditions, fire safety, environmental suitability, and application scenarios to help engineers, EPC contractors, and power system designers make informed decisions.

Understanding Installation Environments for Power Transformers

Transformer installation conditions directly affect system safety, reliability, and lifecycle cost. Common installation environments include:

-

Indoor electrical rooms

-

Outdoor substations

-

Commercial and public buildings

-

Industrial plants and processing facilities

-

Utility distribution and infrastructure projects

Each environment places different demands on cooling, insulation, enclosure design, and safety compliance.

Dry-Type Transformers: Indoor Safety and Clean Power Solutions

Installation Characteristics

Dry-type transformers are typically installed indoors or in enclosed environments, where fire safety, ventilation, and space efficiency are critical.

They are commonly air-cooled (AN/AF) and do not use insulating oil, eliminating the risk of oil leakage or fire caused by flammable liquids.

Typical Ratings

-

Capacity range: 1kVA to 5000kVA

-

Voltage levels: 110V to 35kV

-

Single-phase and three-phase

-

50Hz / 60Hz systems

Key Advantages

-

High fire safety and low environmental risk

-

Suitable for indoor installations close to loads

-

Minimal maintenance requirements

-

Clean operation for commercial and industrial buildings

Common Applications

-

Factories and production lines

-

Data centers and IT facilities

-

Hospitals and public infrastructure

-

Commercial buildings and control rooms

Dry-type transformers are often preferred where personnel safety, environmental protection, and indoor installation are primary concerns.

Oil-Immersed Transformers: High Capacity and Outdoor Reliability

Installation Characteristics

Oil-immersed transformers are typically installed outdoors or in dedicated substations, using insulating oil for cooling and dielectric strength.

They require proper foundations, oil containment systems, and safety clearances, especially in high-capacity and medium-voltage applications.

Typical Ratings

-

Capacity range: 50kVA to 40000kVA

-

Voltage levels: 3kV to 35kV and above

-

Three-phase dominant

-

Designed for continuous duty operation

Key Advantages

-

Higher power density and efficiency

-

Superior heat dissipation for large loads

-

Long service life in utility environments

-

Cost-effective for high-capacity installations

Common Applications

-

Utility distribution networks

-

Substations and grid infrastructure

-

Renewable energy step-up systems

-

Mining, oil & gas, and heavy industry

Oil-immersed transformers remain the preferred choice for utility-scale power systems and high-load outdoor installations.

Safety Considerations: Fire, Environment, and Compliance

When comparing transformer types, safety is a critical selection factor:

| Safety Aspect | Dry-Type Transformer | Oil-Immersed Transformer |

|---|---|---|

| Fire Risk | Very low | Requires fire protection |

| Oil Leakage | None | Oil containment required |

| Indoor Use | Excellent | Limited / Restricted |

| Outdoor Use | Limited | Excellent |

| Environmental Impact | Minimal | Requires management |

Both transformer types can be designed to meet IEC, ANSI, and IEEE standards, with optional UL and CE certification depending on project and market requirements.

Environmental and Climate Adaptability

-

Dry-type transformers are ideal for clean, controlled environments with proper ventilation.

-

Oil-immersed transformers perform better in high-temperature, high-load, and outdoor environments, including harsh industrial and utility conditions.

Selection should consider:

-

Ambient temperature

-

Humidity and dust levels

-

Installation altitude

-

Load cycle and duty rating

How to Choose the Right Transformer Type

When selecting between dry-type and oil-immersed transformers, evaluate:

-

Installation location (indoor vs outdoor)

-

Required capacity and voltage level

-

Fire safety and environmental regulations

-

Maintenance access and lifecycle cost

-

Applicable utility or industrial standards

A properly selected transformer ensures stable voltage, safe operation, and long-term reliability.

Manufacturer Perspective: Engineering Matters

PowerNex is a professional power transformer manufacturer and factory supplier in China, producing dry-type and oil-immersed transformers with capacity ranges from 1kVA to 40000kVA and voltage ratings from 110V to 35kV.

We provide:

-

Standard and custom transformer designs

-

IEC / ANSI / IEEE compliant engineering

-

UL and CE certification options

-

Wholesale supply and project-based solutions

PowerNex supports customers across the United States, Canada, Brazil, Argentina, Mexico, South Africa, Indonesia, Malaysia, and global markets with reliable transformer solutions for industrial and utility applications.

Final Thoughts

Choosing the right transformer type is not just a technical decision—it is a strategic one that impacts safety, reliability, compliance, and total cost of ownership.

Understanding the differences between dry-type and oil-immersed transformers allows engineers and project managers to design power systems that perform safely and efficiently throughout their operational life.