Introduction

In modern industrial environments, electrical safety, power stability, and system reliability are no longer optional—they are essential. As factories become increasingly automated and dependent on sensitive electronic equipment, the quality and safety of electrical power directly affect productivity, compliance, and long-term operational costs.

One key component widely used to address these challenges is the dry-type isolation transformer.

From manufacturing plants and chemical facilities to electronics factories and testing laboratories, dry-type isolation transformers play a critical role in protecting personnel, safeguarding equipment, and improving overall power quality. However, many decision-makers still ask fundamental questions:

-

What types of factories use dry-type isolation transformers?

-

Why are they preferred over oil-filled or non-isolated solutions?

-

How do they improve safety and system performance?

-

What ratings and specifications are typically required?

This in-depth guide answers all of these questions and more. Whether you are an electrical engineer, system integrator, OEM manufacturer, EPC contractor, or industrial buyer, this article provides a practical and comprehensive understanding of dry-type isolation transformers in factory applications.

1. What Is a Dry-Type Isolation Transformer?

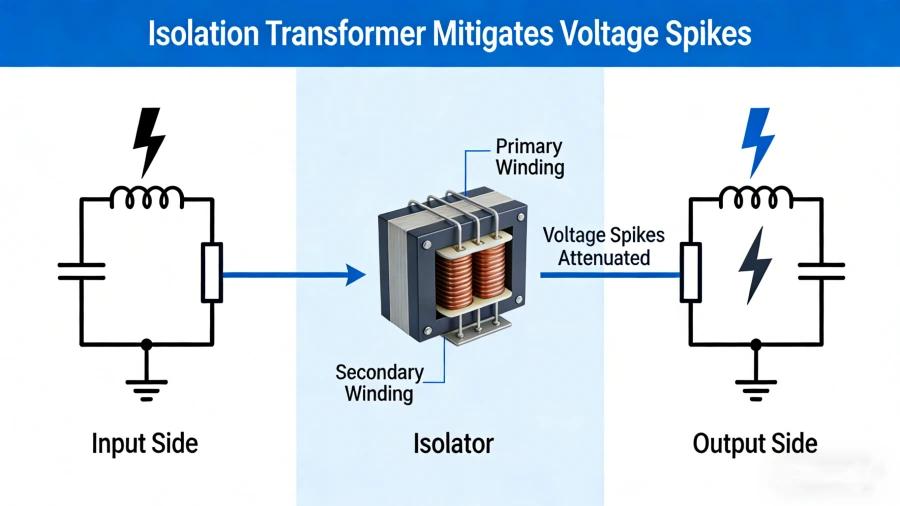

A dry-type isolation transformer is a transformer designed to electrically isolate the input (primary) circuit from the output (secondary) circuit using magnetic coupling, without any direct electrical connection and without liquid insulation such as oil.

Key characteristics include:

-

Galvanic isolation between primary and secondary windings

-

Air-cooled or resin-insulated construction

-

No oil, no leakage risk, and reduced fire hazard

-

Suitable for indoor and environmentally sensitive installations

Most dry-type isolation transformers operate with a 1:1 voltage ratio, meaning the output voltage equals the input voltage, but the electrical separation significantly improves safety and power quality.

2. Why Factories Use Dry-Type Isolation Transformers

Industrial factories face unique electrical challenges:

-

High fault currents

-

Electrical noise from motors and drives

-

Sensitive control systems

-

Frequent human interaction with electrical equipment

-

Strict safety and regulatory requirements

Dry-type isolation transformers address these issues through several core functions.

2.1 Electrical Safety Enhancement

Electrical isolation reduces the risk of electric shock by eliminating a direct return path to ground. In maintenance areas, test stations, and control rooms, this feature is critical for protecting technicians and operators.

2.2 Protection of Sensitive Equipment

Isolation transformers prevent disturbances on the utility side—such as voltage spikes, ground faults, or noise—from propagating to downstream equipment.

2.3 Power Quality Improvement

By reducing common-mode noise and breaking ground loops, isolation transformers provide cleaner, more stable power for electronic systems.

2.4 Compliance with International Standards

Dry-type isolation transformers are commonly designed to meet standards such as:

-

UL / cUL (North America)

-

IEC / EN (Europe)

-

IEEE recommendations

-

Local electrical codes in Latin America and other regions

3. Types of Factories That Commonly Use Dry-Type Isolation Transformers

3.1 Industrial Automation and Machinery Manufacturing Plants

Typical equipment:

-

CNC machines

-

PLC control cabinets

-

Industrial robots

-

Servo drives and motion control systems

Why isolation is required:

Automation systems rely on precise control signals that are highly sensitive to electrical noise. Dry-type isolation transformers protect PLCs and control electronics from disturbances caused by motors, welding equipment, and variable frequency drives (VFDs).

3.2 Electronics and Semiconductor Manufacturing Factories

Examples:

-

PCB fabrication plants

-

SMT assembly lines

-

Semiconductor packaging and testing facilities

Key requirements:

-

Extremely stable voltage

-

Low electrical noise

-

Protection for sensitive measurement equipment

Isolation transformers ensure clean power delivery and reduce the risk of costly equipment damage or product defects caused by power anomalies.

3.3 Chemical and Pharmaceutical Factories

Application areas:

-

Distributed control systems (DCS)

-

Instrumentation power supplies

-

Laboratory and analysis rooms

Why dry-type matters:

In hazardous or controlled environments, dry-type transformers eliminate the fire and leakage risks associated with oil-filled units while meeting strict safety and hygiene requirements.

3.4 Food and Beverage Processing Plants

Typical use cases:

-

Automated packaging lines

-

Conveyor systems

-

Control panels in washdown areas

Dry-type isolation transformers are ideal for indoor installations where cleanliness, moisture resistance, and safety are critical.

3.5 Medical Equipment Manufacturing Facilities

Applications:

-

Diagnostic equipment production

-

Medical device testing stations

Isolation transformers help manufacturers meet medical safety standards and protect both personnel and sensitive equipment during production and testing.

3.6 Data Center and IT Equipment Manufacturing Plants

Used for:

-

Server testing

-

UPS and PDU production

-

Network equipment validation

Isolation transformers reduce ground loop issues and electromagnetic interference that can affect performance testing and reliability.

3.7 Renewable Energy and Power Equipment Factories

Examples:

-

Inverter manufacturing

-

Energy storage system production

-

Power electronics testing labs

They provide safe, isolated power during functional testing and commissioning of high-value equipment.

3.8 R&D Centers and Industrial Test Facilities

Common scenarios:

-

Product development labs

-

High-voltage testing

-

Certification and compliance testing

Isolation transformers protect engineers and allow controlled testing without interference from the main power grid.

4. Common Power Ratings Used in Factories

Dry-type isolation transformers are available in a wide range of capacities to suit different factory needs.

4.1 Small Control and Instrumentation Ratings

-

100 VA

-

250 VA

-

500 VA

-

1 kVA

-

2 kVA

-

5 kVA

Used for control circuits, sensors, and small equipment.

4.2 Medium Commercial and Industrial Ratings

-

10 kVA

-

15 kVA

-

20 kVA

-

30 kVA

-

50 kVA

Common for control panels, automation lines, and localized power distribution.

4.3 Large Industrial Ratings

Used for entire production lines, test systems, and large industrial loads.

5. Dry-Type vs Oil-Filled Isolation Transformers

| Feature | Dry-Type | Oil-Filled |

| Fire risk | Low | Higher |

| Indoor use | Ideal | Restricted |

| Maintenance | Minimal | Regular oil checks |

| Environmental risk | None | Possible oil leakage |

| Installation | Flexible | Heavier, more regulated |

For most factories, dry-type isolation transformers are the preferred solution due to safety, simplicity, and compliance advantages.

6. Key Selection Factors for Factory Applications

When selecting a dry-type isolation transformer, consider:

-

Primary and secondary voltage ratings

-

Required kVA capacity

-

Single-phase or three-phase configuration

-

Insulation class and temperature rise

-

Enclosure type (open, ventilated, IP-rated)

-

Noise level requirements

-

Compliance with local and international standards

Working with an experienced manufacturer or supplier helps ensure proper sizing and long-term reliability.

7. Why Source Dry-Type Isolation Transformers from a Professional Manufacturer

For industrial and factory use, sourcing directly from a qualified manufacturer offers:

-

Consistent quality control

-

Customizable specifications

-

Compliance documentation

-

Technical support during design and installation

-

Stable supply for bulk or repeat orders

This is particularly important for OEMs, system integrators, and EPC contractors working on large or long-term projects.

Conclusion

Dry-type isolation transformers are a foundational component in modern factory electrical systems. They enhance safety, protect sensitive equipment, improve power quality, and help industrial facilities meet increasingly strict standards and performance expectations.

From automation plants and electronics factories to chemical facilities and R&D centers, their role is both practical and strategic. Understanding where and why they are used allows engineers and decision-makers to design safer, more reliable, and more efficient industrial power systems.

For factories operating in today’s demanding global environment, dry-type isolation transformers are not just an option—they are a necessity.