Working Principles, Capacity Ranges, and Industrial Applications

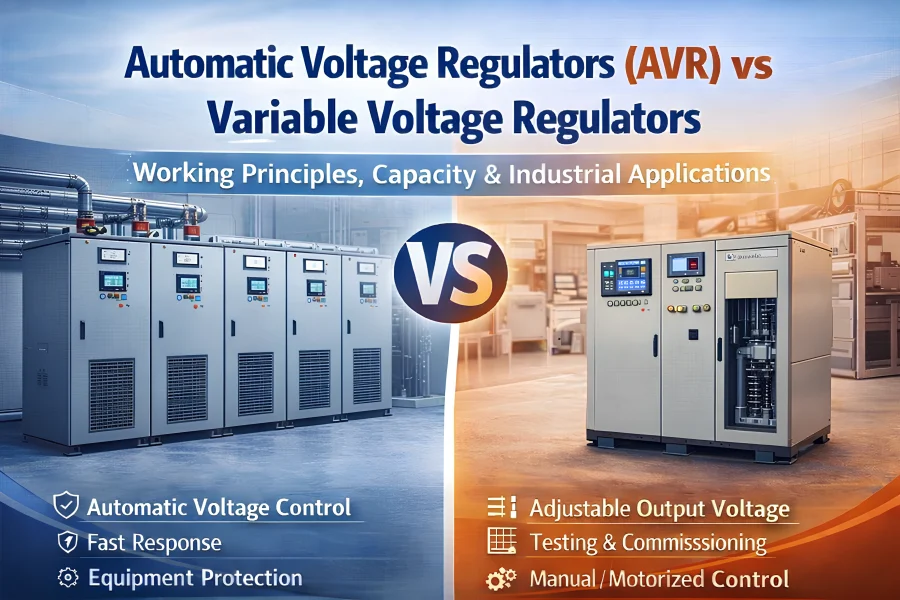

Stable voltage is critical for the safe and efficient operation of industrial power systems. Voltage fluctuations can cause equipment malfunction, production downtime, and long-term electrical damage. To address these challenges, Automatic Voltage Regulators (AVR) and Variable Voltage Regulators are widely used across industrial, commercial, and utility applications.

This article explains the differences, working principles, capacity ranges, voltage ratings, and application scenarios of AVR systems and variable voltage regulators, helping engineers and project planners select the right voltage control solution.

What Is an Automatic Voltage Regulator (AVR)?

An Automatic Voltage Regulator (AVR) is designed to maintain a stable output voltage automatically, regardless of fluctuations in input voltage or load conditions.

Key Characteristics of AVR Systems

-

Automatic voltage correction without manual adjustment

-

Fast response to voltage drops and surges

-

Designed for continuous operation

-

Ideal for protecting sensitive electrical equipment

Typical AVR Electrical Parameters

-

Capacity range: 1 kVA – 5000 kVA

-

Input voltage: 110V – 35kV (customizable)

-

Output voltage accuracy: ±1% to ±3%

-

Frequency: 50Hz / 60Hz

-

Phase: Single-phase & three-phase

AVR systems are commonly used in environments where voltage instability is frequent but constant output voltage is required.

What Is a Variable Voltage Regulator?

A Variable Voltage Regulator allows users to manually or electronically adjust output voltage within a defined range. Unlike AVR systems, variable voltage regulators do not automatically correct voltage fluctuations unless controlled by an external system.

Key Characteristics of Variable Voltage Regulators

-

Adjustable output voltage

-

Suitable for testing, commissioning, and process control

-

Supports gradual voltage variation

-

High mechanical and electrical durability

Typical Variable Voltage Regulator Parameters

-

Capacity range: 1 kVA – 3000 kVA

-

Voltage adjustment range: ±5% to ±30%

-

Input voltage: 110V – 35kV

-

Frequency: 50Hz / 60Hz

-

Control type: Manual or motorized

These systems are widely used in laboratories, production testing, industrial machinery, and voltage-sensitive processes.

AVR vs Variable Voltage Regulator: Key Differences

| Feature | Automatic Voltage Regulator | Variable Voltage Regulator |

|---|---|---|

| Voltage control | Fully automatic | Manual or motorized |

| Response speed | Fast, real-time | Adjustable, slower |

| Output stability | Constant voltage | Variable voltage |

| Best use | Equipment protection | Testing & process control |

| Operation | Continuous | Adjustable / intermittent |

Industrial Applications of Voltage Regulation Systems

Manufacturing & Processing Plants

-

Stabilizing voltage for CNC machines and automation systems

-

Protecting motors and VFD-driven equipment

-

Reducing electrical stress and downtime

Utilities & Infrastructure Projects

-

Voltage stabilization in distribution networks

-

Supporting transformers and substations

-

Improving power quality in regional grids

Commercial & Critical Facilities

-

Data centers and IT infrastructure

-

Hospitals and medical equipment

-

Airports and transportation systems

Testing & Commissioning

-

Electrical equipment testing

-

Load simulation

-

Voltage tolerance verification

Capacity & Voltage Selection Guidelines

When selecting an AVR or variable voltage regulator, engineers should evaluate:

-

Load capacity (kVA) and starting current

-

Input voltage range and grid conditions

-

Required voltage accuracy

-

Duty cycle and operating environment

-

Compliance with IEC, ANSI, IEEE, UL, or CE standards

Proper sizing ensures long-term reliability and optimal system performance.

Manufacturing, Customization & Global Supply

As a professional power equipment manufacturer and factory-based supplier, PowerNex provides:

-

Standard and customized AVR systems

-

Industrial variable voltage regulators

-

OEM and wholesale solutions

-

UL, CE, and IEC-compliant designs

Our voltage regulation products are manufactured in China and supplied globally, including:

USA, Canada, Brazil, Argentina, Mexico, South Africa, Indonesia, Malaysia, and other international markets.

Conclusion

Both Automatic Voltage Regulators (AVRs) and Variable Voltage Regulators play essential roles in modern power systems. Understanding their differences in control method, capacity range, and application scenarios helps ensure the right solution for each project.

Automatic Voltage Regulators are designed to maintain a stable output voltage automatically despite fluctuations in input supply or load conditions. Typical AVR systems cover capacity ranges from 10kVA, 15kVA, 30kVA, 60kVA, 100kVA, 150kVA, 300kVA, and extend to multi-MVA engineered solutions, supporting voltage classes from low-voltage industrial networks to medium-voltage systems up to 35kV. They are widely applied in industrial production lines, utility distribution networks, renewable energy integration, and critical infrastructure requiring continuous voltage stability.

Variable Voltage Regulators, on the other hand, allow manual or programmable voltage adjustment across a defined range, making them ideal for applications where controlled voltage variation is required. Common capacity options include 5kVA, 10kVA, 20kVA, 30kVA, 100kVA, 200kVA, and higher custom-built ratings, typically operating in single-phase or three-phase low-voltage systems. These regulators are frequently used in testing laboratories, equipment commissioning, R&D environments, and specialized industrial processes.

Whether for industrial production, utility infrastructure, or specialized testing environments, selecting the proper voltage regulation equipment—automatic or variable—is key to achieving stable, efficient, and safe electrical operation.

Looking for reliable voltage regulation equipment for your next project?

Contact PowerNex today for specifications, quotations, and OEM or wholesale solutions. We support global customers with stable, engineered power control systems.